Peut-on mélanger plusieurs marques de pâtes?

Que faites-vous des « restes »?

Merci i et belle journée. Prenez soin de vous.

Merci de ce que vous faites pour nous.

The polymer clay cane technique allows you to create a variety of patterns by working a strand of clay and cutting it into thin slices. Geometric canes are simpler to make than figurative ones, and their preservation requires tightly wrapping them to prevent drying. For best results, it's advisable to follow tutorials and experiment with different patterns and techniques.

There are many ways to work with polymer clay: modeling, surface work, finding color effects, textures and as many other techniques as there are creative ideas in a head. Here we will focus on one of the most used practices: the cane. We will see how to make a Fimo clay cane and how to reduce a Fimo clay cane, how to cut regular slices, how to use Fimo canes and finally how to store them properly. Of course, this also works with other polymer pastes!

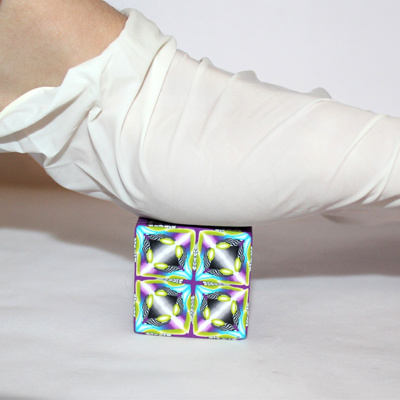

A cane (you will sometimes find the spelling "cane") is a sausage of dough in which you have set a pattern and you will cut thin slices that you can use in several ways. There are an infinite number of types of canes and once you get the hang of it, you'll quickly invent your own. It should be noted, however, that figurative canes require a little more rigor than geometric and abstract canes.

The basic canes are the gradient cane (Find the complete step by step to make a gradient cane by following this link : black and white gradient duck slice ornament) and its little sister, the spiral duck, but there are more complex duck patterns of flowers, butterflies, mosaics or kaleidoscopes.

The principle is always the same: you make a large assembly of different pieces of dough, then weld the elements together by pressure and reduce your "sausage" to a smaller diameter before cutting slices. You will find an incredible number of tutorials to follow step by step in order to make your first canes. (You can find the creation of an iris cane here). Once your assembly is finished comes the most delicate step, namely the reduction.

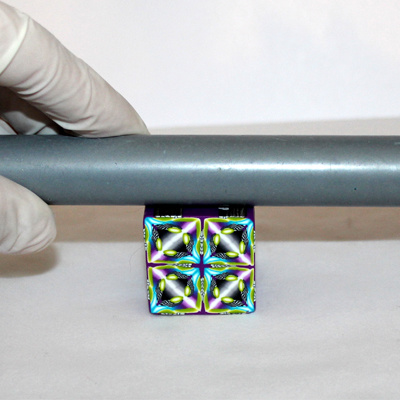

How to reduce a cane in Fimo clay? Properly reduce a cane is to reduce its diameter and stretch its length without distorting the design that you have made in its heart so that once this step is finished, all the slices extracted from the cane are identical to each other. For this, there are several simple rules to follow. First of all, don't just grab the ends of your cane and pull on it, you risk getting big deformations of your pattern and consequently, loss of material. Instead, push the material inward, as if you were trying to get all the elements of your cane closer and closer together. If your cane is round, finish by rolling it on your table to make it perfectly even.

Square section canes are the easiest to stretch, as you simply use your work surface to apply pressure with the flat of your hand or a roller on each side of your cane. Press (not too hard) and rotate your cane regularly on its next side to obtain the most regular reduction possible.

How to cut Fimo canes? Once the cane completed and reduced to the diameter that suits you, place it in the refrigerator on a piece of parchment paper for at least half an hour. Indeed, the multiple manipulations that you have just inflicted softened the material and you now need it to harden a little to exploit easily.

Be careful, you will be tempted to reduce the hardening time by placing it in the freezer, but we advise you to avoid it; if you forget it, it may be complicated to use it by yourself.If you forget, it may be difficult to use it later. Moreover, during its passage in the freezer, the dough gets covered with moisture, which will also make it difficult to handle. Once the dough has hardened enough, grab your blade and gently cut even slices.

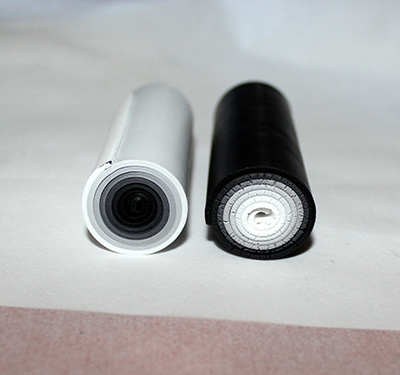

Here's a tip for cutting slices from a round cane without crushing. Prepare a base with a good piece of yuck dough (yuck dough = scraps of mixtures or leftover unworkable cane ends). Shape it into a rectangle at least as long as your cane and a little wider. Use a rounded object like a roller to give it a curved surface and cover it with cling film. Lay your cane down with a round section and cut your slices. Your slices won't crush like they would on a flat work surface and the cling film will prevent the yuck dough from sticking and messing up your cane.

You can also use a Slicer (a dough slicer) to make more even slices.

How to use the Fimo canes? You can use your slices in different ways.

By cutting wide enough slices, you will get round and flat beads that you will have to drill in the thickness. You can also cut thinner slices and simply pierce them like a medal. To make ball beads, cut thin slices and cover a small ball of raw butter dough. Roll the bead in your hands to smooth the joints of the slices and then pierce (before or after baking).

Finally, you can also prepare thin slices and cover a sheet of raw dough, smooth it with parchment paper and a roller and then cut out the pearls of your choice.

If you are afraid of creating ducks or if it's just not your "thing", there are pre-baked patterned polymer ducks, as well as sliced ducks that you can easily get. They are, for the most part, small diameter canes ready to use.

You will find different representations such as fruits, butterflies, symbols, flowers, etc.. You can include them in polymer clay creations, glue them on a surface or whatever your imagination tells you to do.

Wrap your cane or what's left of it in a piece of crystal paper (preferably, but you can also use cling film), stretching it as tightly as possible so that you don't make any "crumple" marks on the clay. Then place it in an airtight box. The principle is very simple, in order to be preserved by drying as little as possible, the polymer clay must be kept away from air and light.

These are the basics of what you need to know about polymer clay cane. Now you can try out different levels of complication by following tutorials or by creating your own cane!

Thanks to La perle rouge for this technical sheet!

Copyright La perle rouge.

All rights reserved. Reproduction, even partial, is forbidden without the author's agreement. You can find all his models on the websitehttps://bloglaperlerouge.wordpress.com/

Credits

Perles & Co, Internet & E-Commerce company [04/03/2021] Any reproduction, representation, adaptation, in any form whatsoever, even partial, is prohibited, except for reproduction for private use not intended for collective use, representation in the family circle (art. L 122-5 CPI) and online publishing on condition that the source is mentioned and a link is included to the corresponding page of our site www.perlesandco.com.