Stranded wire, made of stainless steel strands and coated with nylon, is the strongest material for jewelry-making. For maximum flexibility and strength, opt for 49-strand wire, while for stiffer creations, 7-strand wire will suffice. The Beadalon and Griffin brands offer wires for general use, while Soft Flex offers options tailored to specific applications.

Stranded wire is made up of several small strands of stainless steel, braided together and covered with a nylon sheath. It is the strongest material available for jewelry-making. It can support very heavy beads, depending on the diameter of the wire and the number of strands.

The higher the number of strands, the more flexible and resistant the cord. For example, 49-strand stranded wire is more flexible than 7-strand stranded wire. The finer it is, the more flexible it will appear.

On the other hand, the more strands there are in a corded wire, the more expensive it is for a similar diameter and length. Since it's made of stainless steel, it won't rust.

There are several factors to consider when choosing a jewelry wire. Some very specific jewelry pieces require rigid wires to create volume in the design. Most of the time, however, you'll need a strong, flexible wire. You should also note the hole diameter of the beads you'll be using and the strength required to hold your creation in place.

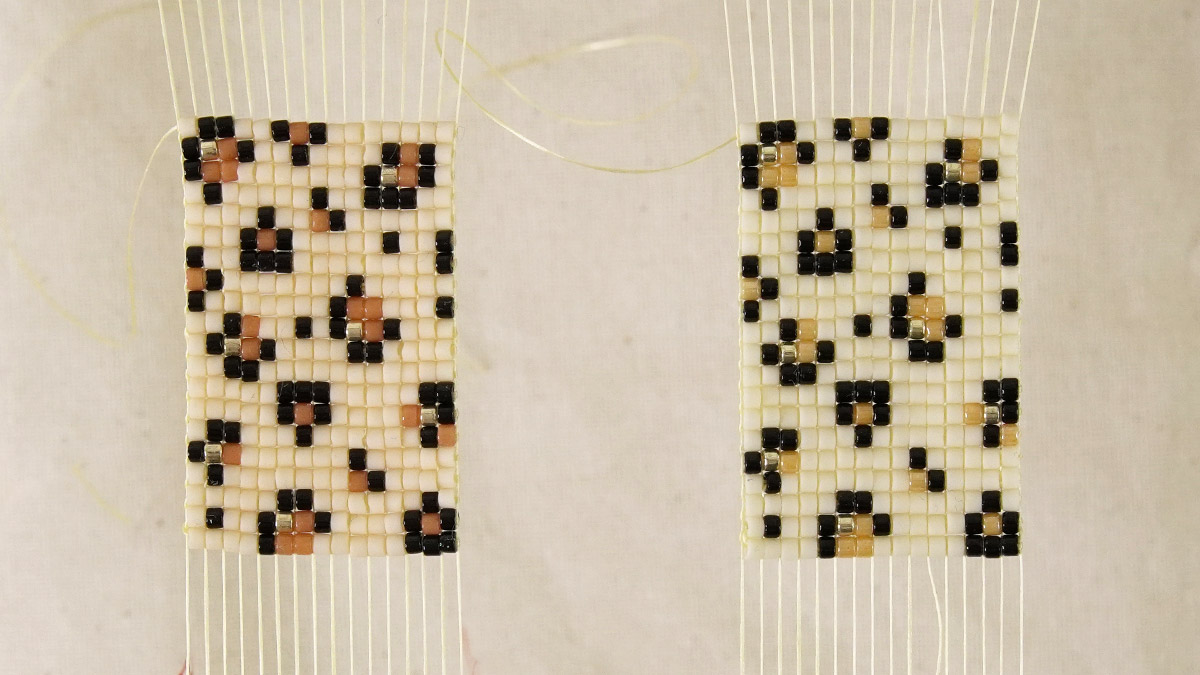

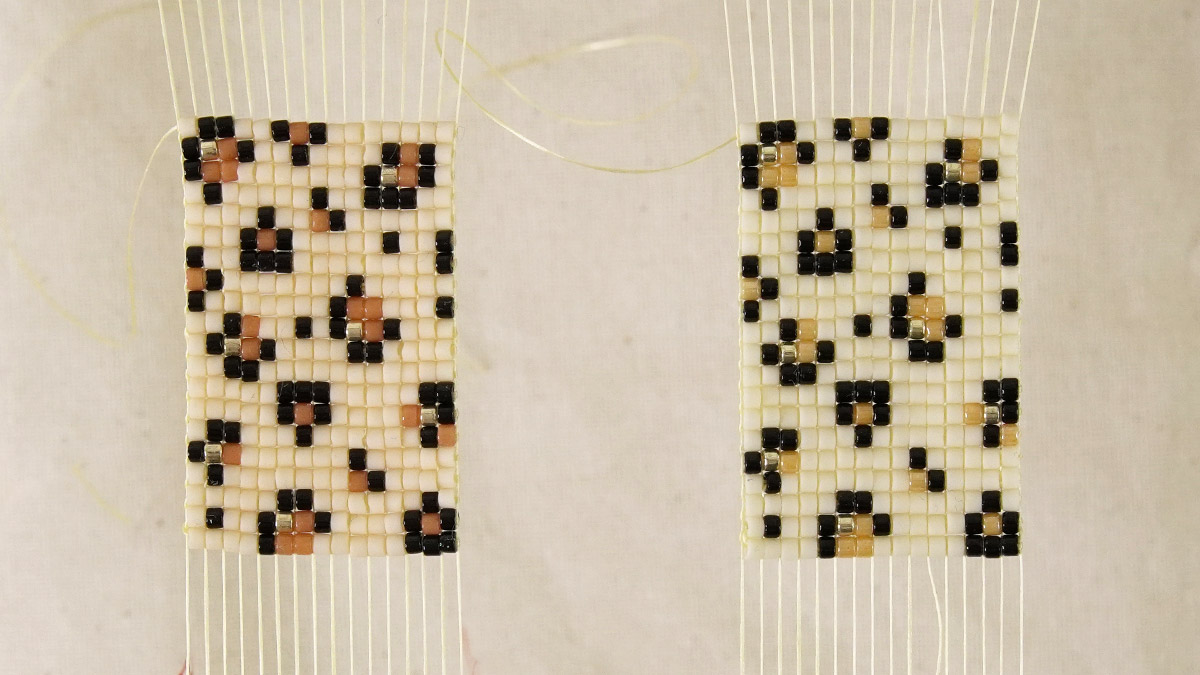

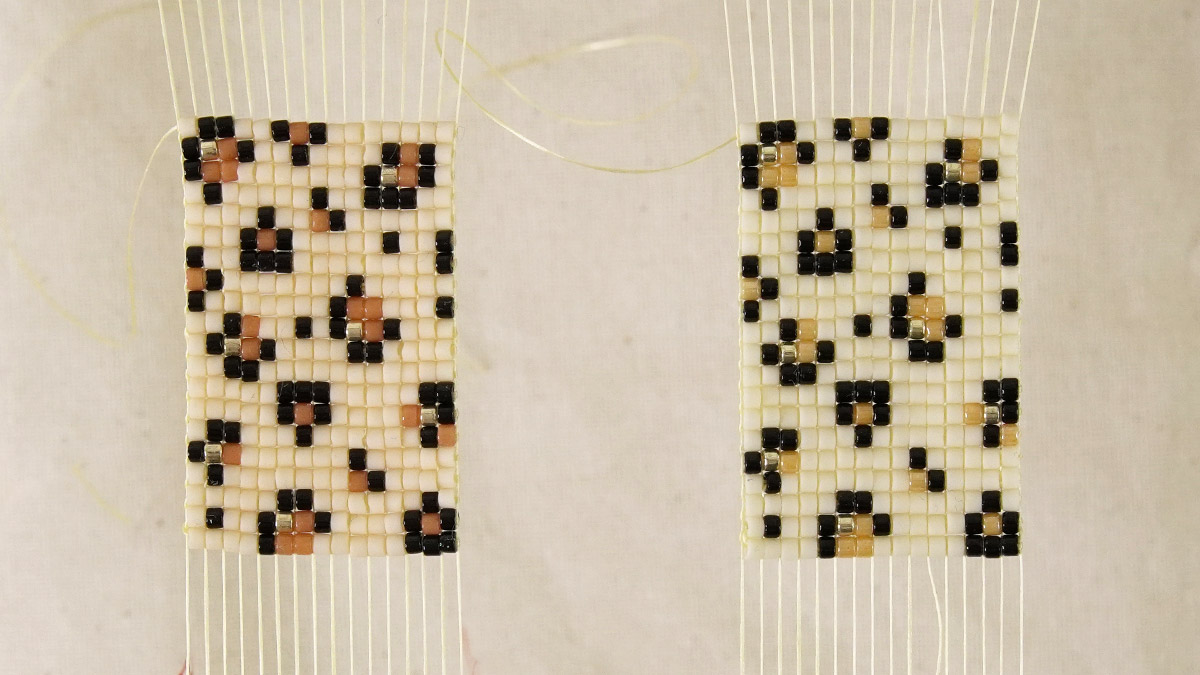

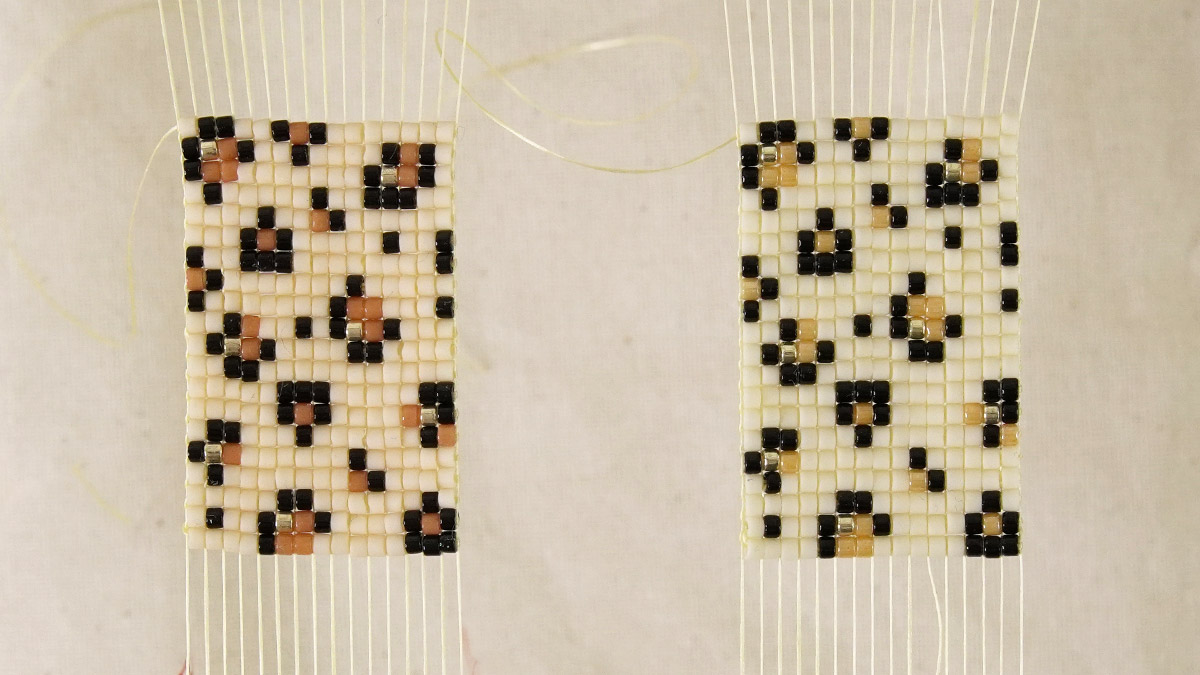

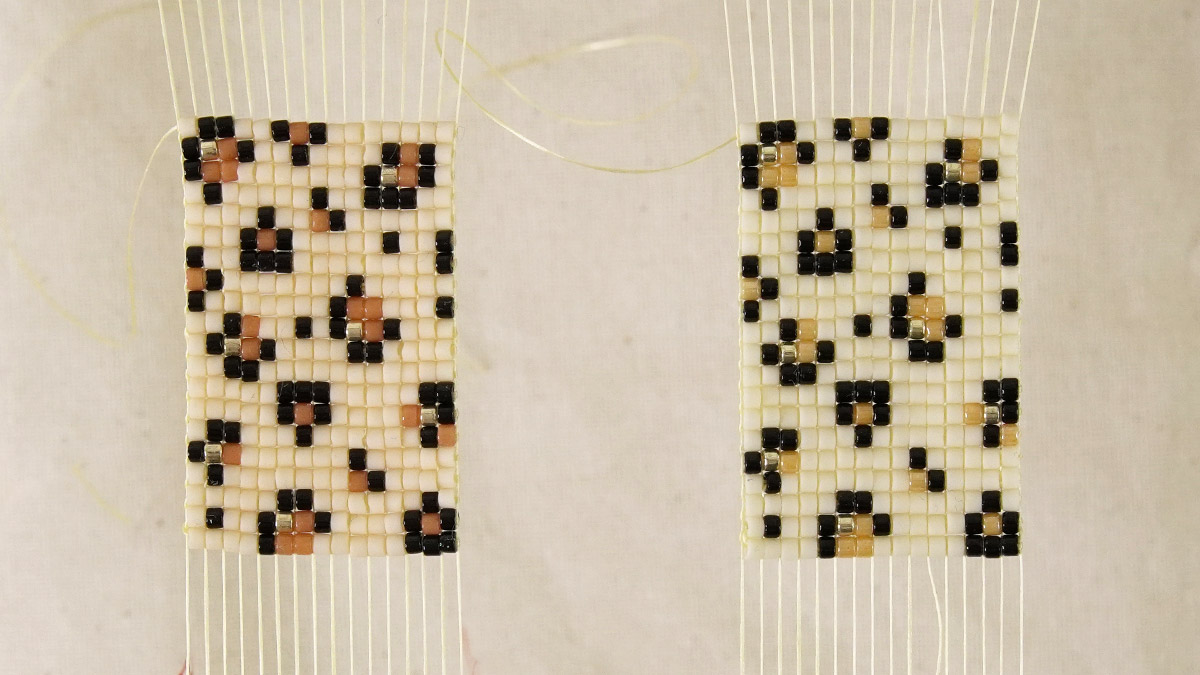

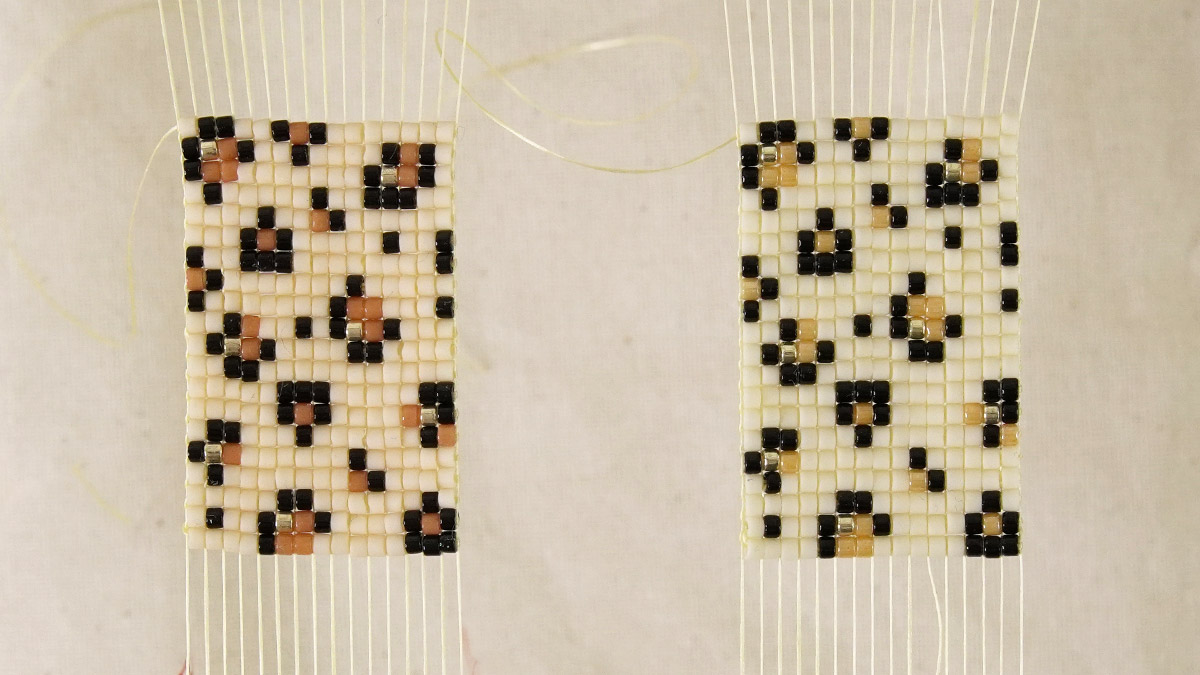

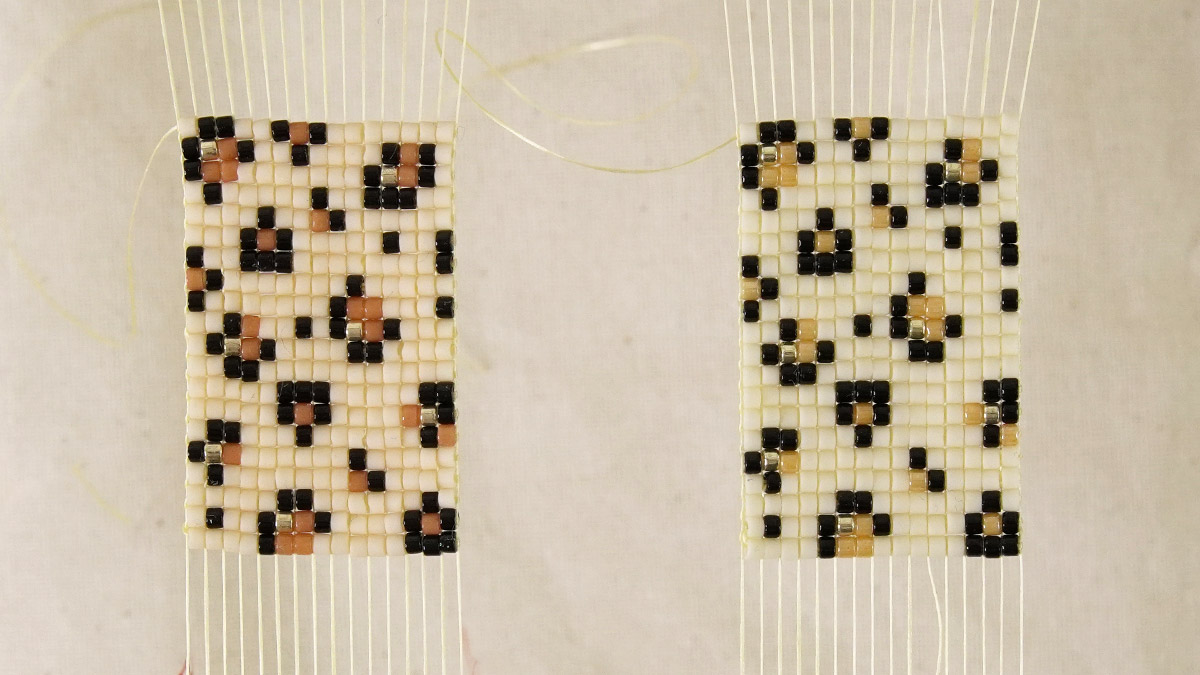

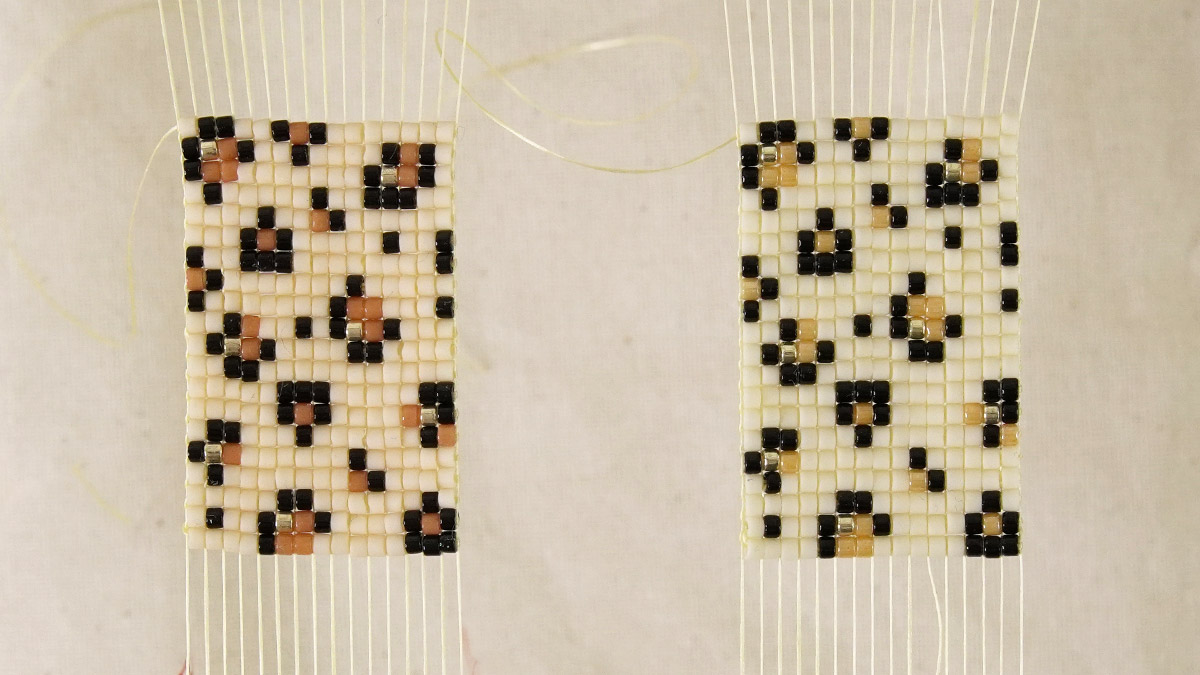

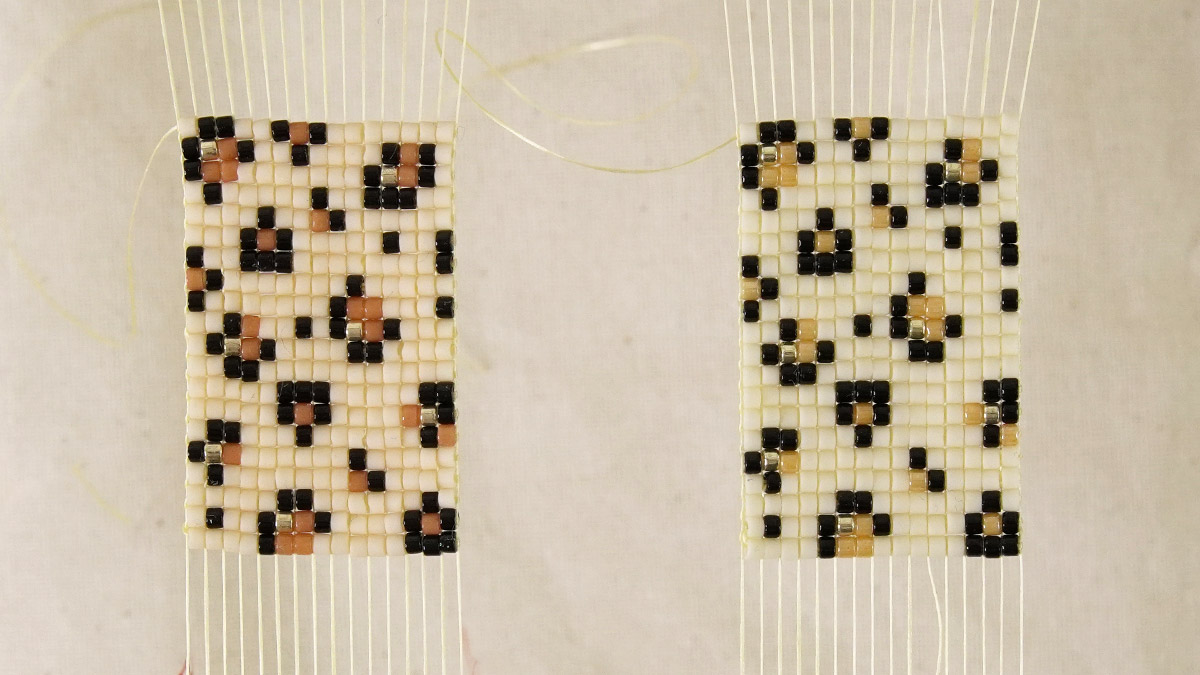

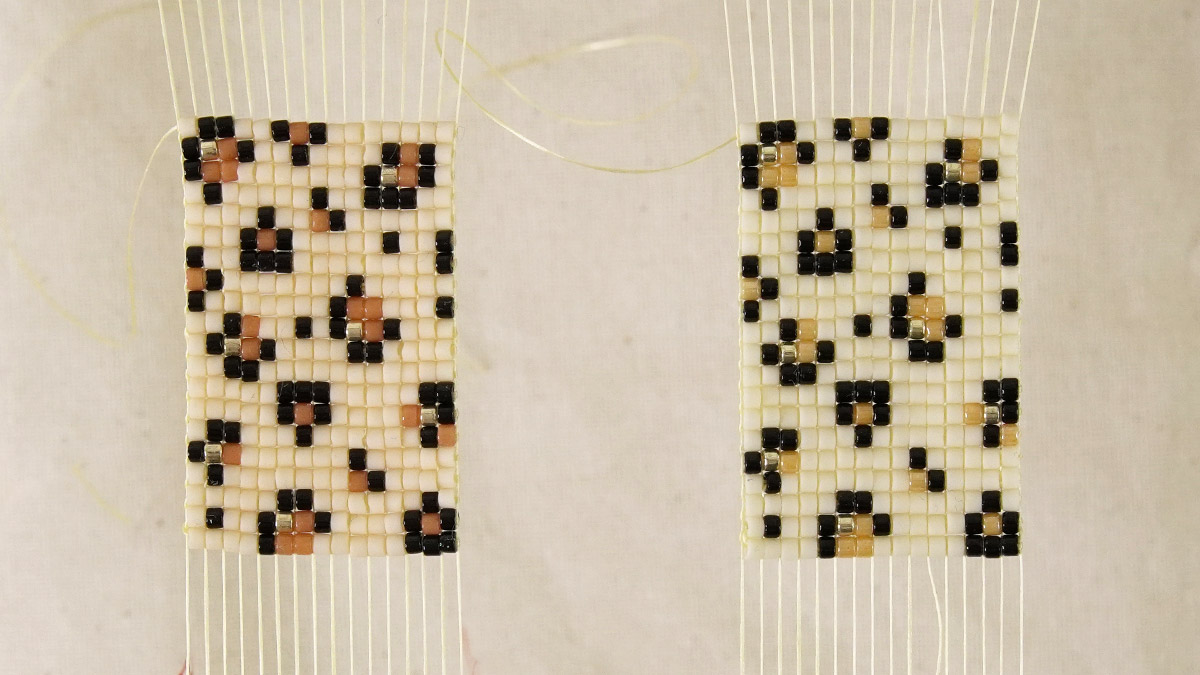

Above is an example of how to finish a piece of wire jewelry. You don't knot the wire to finish your creation. You need to use Crimp beads, Crimp bead covers (optional), and wire protectors (optional). We invite you to see how it's done in this article: What are wire protectors?

Look at which bead has the smallest hole diameter. Your wire should not exceed this diameter. As with any attractive finish, you need to be able to pass the wired threads through the beads at the end a second time. The hole in the beads near the end of the jewel must be twice as large as your wired thread.

Wired wire comes in a wide variety of diameters, from 0.25 mm ideal for Seed beads, to 0.91 mm more suited to glass beads. The most commonly used wire diameters range from 0.36 mm to 0.46 mm.

Of course, the thicker your wire, the more strands it will have and the more resistant it will be, provided the jewel is closed correctly. So sometimes you have to make concessions or change the beads near the clasp so that they have a slightly larger hole.

You also need to think about how flexible you want your creation to be. Unless your creation requires your wire to remain in the air, as in the case of wedding necklaces composed of several aerial wires, or the wire used is very fine (less than 0.38 mm), then there's little point in choosing 7-strand.

Choose 49-strand twisted wire when your creation requires great flexibility and strength. Choose 19-strand stranded wire when your creation requires good flexibility, and 7-strand stranded wire when your creation requires medium flexibility.

Finally, the strength of the setting will vary according to the weight of your creation, the frequency with which you intend to wear it, and the quality of the finish used to close the jewel.

Very often, when a piece of jewelry breaks, the break occurs at the clasp or at a point that has been weakened by a fold.

The strength of your creation will depend on a good crushing technique for the beads to be crushed. Indeed, poor crushing can weaken the wired thread, which will tend to break at the level of the bead to be crushed. Flat pliers will crush the strands and weaken the wire. Many people still use this method rather than the one described below, as it's much easier to do.

But if your necklaces and bracelets break regularly and quickly, you may want to change the way you finish your jewelry first. We invite you to use pliers specifically designed for crushing beads. These pliers are available for different sizes of Crimp beads. Follow the steps illustrated below or our technical sheet to learn how to make beautiful finishes with Crimp beads.

Choose Crimp beads with a hole slightly larger than the diameter of your wire x2 :

There are several different brands of cabled wire. The best-known are Beadalon wires. There's also the Griffin brand.

Lately, we've been introducing new Soft Flex wires. This brand is of very high quality, but above all, it has the advantage of designing its wires for a specific use, unlike Beadalon and Griffin, which make wires for a more generic use.

On each product page, you'll find out for which use the wire is intended. For example, for Seed beads and freshwater pearls, for heavy glass beads and for certain other specific techniques...

Credits

Perles & Co, Internet & E-Commerce company [18/03/2020] Any reproduction, representation, adaptation, in any form whatsoever, even partial, is prohibited, except for reproduction for private use not intended for collective use, representation in the family circle (art. L 122-5 CPI) and online publishing on condition that the source is mentioned and a link is included to the corresponding page of our site www.perlesandco.com.